Mercury Pump Power Puck and UV LED Power Puck

The UV power puck is a professional device for detecting the intensity and energy of UV light sources. It is mostly used for curing lamp intensity and energy detection in the UVA band. At present, UV power pucks are mainly used for detecting mercury lamps and UV LED light sources. By understanding the difference between the two sources, we can know why it is necessary to distinguish between mercury lamps and UV LED power puck.

Mercury lamp curing and mercury lamp special UV power puck

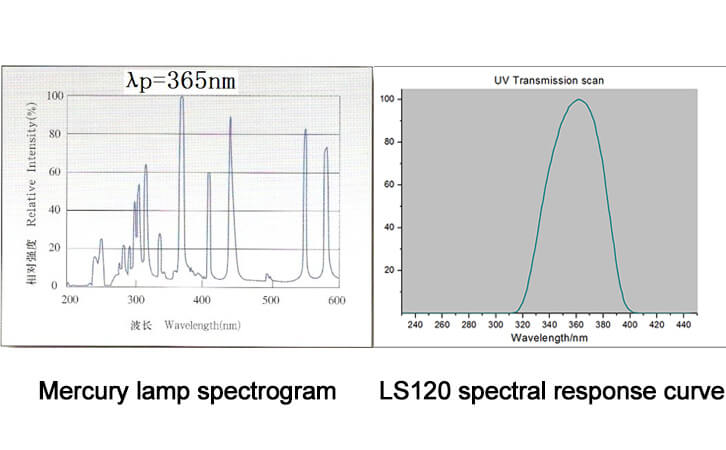

The principle of mercury lamp curing is to add a certain amount of mercury inside the lamp tube. Under the high pressure of the power source, the mercury inside the lamp tube is atomized to emit ultraviolet light to complete the whole work. However, in addition to ultraviolet light, ultraviolet high-pressure mercury lamps emit light of other wavelengths. From the following figure, we can also see that the mercury lamp has a wide spectral curve and the light emitted by it contains ultraviolet light, visible light and infrared light. However, the curing wavelength is a peak of ultraviolet 365 nm.

Therefore, the spectral response of the UV power puck designed for mercury lamp intensity and energy detection is concentrated at the peak of 365 nm and the spectral influence range is 315-400 nm.

UV LED curing and UV LED power puck

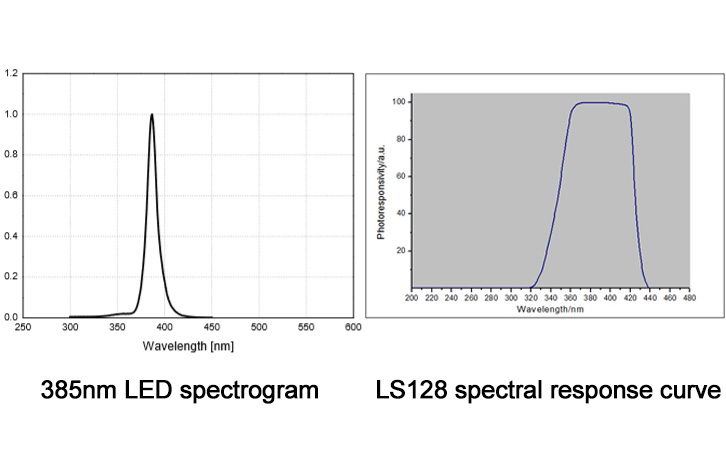

Ultraviolet LED, also known as UV diodes, are a number of UV bulbs arranged in a way that achieves ultra-high wattage and uniform light source. In industrial production, reliable, stable and shorter curing time is an important indicator. LED UV curing machine has many advantages over traditional mercury lamp UV curing machine: LED UV curing machine has no heat radiation, low energy consumption and environmental protection. No pollution, simple installation and space saving. In addition, compared with mercury lamps, the biggest characteristic of LED is that the light emitted by them is mainly concentrated in a specific wavelength band, and does not generate light of other wavelengths. In addition to the long service life, the use of LED light sources can help customers reduce input and costs.

UV LED commonly used in curing machines are mainly 365nm, 385nm, 395nm and 405nm. Therefore, the UV LED power puck and the mercury lamp-specific power puck have different spectral receiving ranges. As shown in the above figure, the UV LED power puck has no spectral peak receiving curve, but exhibits a basic response at 365-405 nm. In the same situation and the LED light source is basically a narrow spectrum, the intensity and energy of different LED light sources can be detected.

From the above two figures, we can easily find the difference between the mercury lamp and the UV LED power puck in the spectrum receiving curve. The diversity of LED light sources makes the traditional UV power puck for mercury lamps no longer suitable for all LED curing machines. Therefore, the emergence of UV LED power pucks is also the inevitable result of the rapid development of LED curing applications.