UV Integrator for High Pressure Mercury Lamps

High-pressure mercury lamps are UV-cured standard lamps that generate large heat and are cooled by air or water. The high pressure mercury lamp has high power and is suitable for light-curing coatings and ink-coated lines that require fast curing rates.

The spectral curve of the high-pressure mercury lamp is mainly in the ultraviolet portion, such as 253.7 nm, 303 nm, 334 nm, 365 nm, 366.3 nm, etc., wherein the curves of 365 nm and 366.3 nm are extremely advantageous and are valuable in the process of UV curing. Because many the photoinitiator system has a strong absorption in this area. Therefore, high pressure mercury lamps are also called UV curing lamps.

During the curing process of the high-pressure mercury lamp, the intensity of the ultraviolet light source will decay with time. It is invisible to the naked eye and a professional testing instrument---UV integrator must be used.

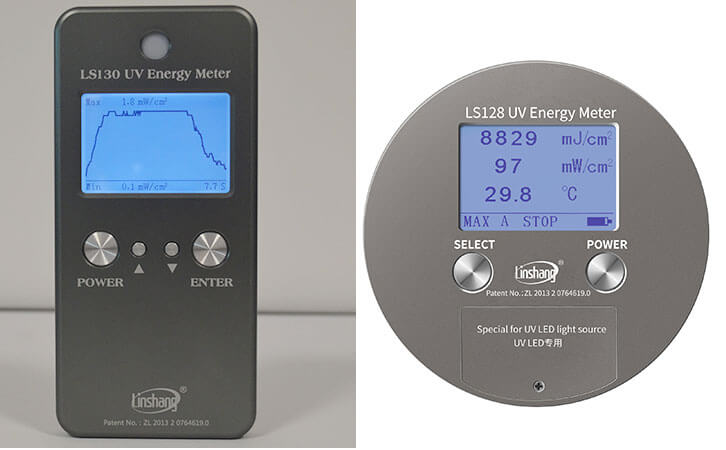

The UV integrator LS130 produced is ideal for measuring the intensity and energy of high-pressure mercury lamps, halogen lamps and other light sources. And when testing, the real-time power value, power maximum value, energy value and measurement duration can be displayed simultaneously. By looking at the power curve of the instrument, you can analyze the distribution of the intensity of the light source.

High-pressure mercury lamps are mainly used for ink curing, photo printing, paper glazing, flexible packaging color printing, bamboo flooring, paint coating, curing of electronic components, plastic and rubber aging experiments and various UV curing. The UV integrator LS130 is also suitable for these industries.