The Benefits of UV Curing and The Role of UV Energy Meter

UV curing machine has been widely used in plastic, electronics, lighting, automotive, handicrafts and glass industry. Then what are the advantages of using UV curing machine?

1. The automatic operation of the machine can reduce labor costs and improve production efficiency;

2. Can reduce solvent evaporation, thereby reducing air pollution;

3. Small equipment space is required, can reduce plant costs;

4. Can provide controllable monitoring for the production process and improve the passing rate of the finished product.

However, sometimes the ink is not dry during the UV curing process, that's mainly because of the following points:

1. UV curing light source attenuation causes received UV energy per unit time (in units of mJ / cm2) is not enough;

2. UV curing lamp and ink drying coefficient does not match;

3. Ink curing is not done immediately after the completion of ink printing or it has been placed for a long time before UV curing, the chemical composition of the ink has been volatilized or deteriorated;

4. UV light source is not directly exposed to the ink surface, so received energy is not enough to make the ink completely cured.

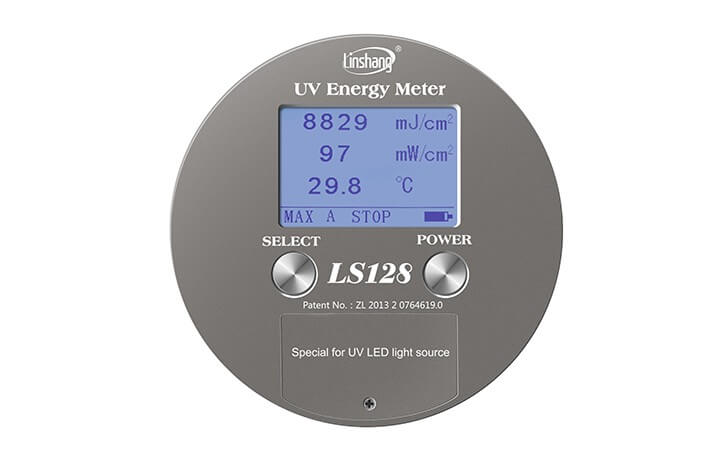

These problems arise mainly because the UV power, energy and irradiation time required by the product in curing are not well controlled. How much UV intensity is enough and how much energy is needed to cure the ink,you need a professional UV Energy Meter to monitor the curing process of the UV lamp in real time. And it is also necessary to equip a professional personnel to record the data, time, energy and intensity, then to analyze and fix plan to monitor the operation of the machine.