UV Integrator Calibration of UV Energy Meter Manufacturer

The UV Integrator is mainly used to detect the UV light source intensity and UV energy value of the UV curing device. The stability of the UV energy meter is directly related to the quality of the cured product. The use of a UV Integrator requires regular calibration of the instrument. Many customers don't know much about the calibration of UV energy meters. We will briefly introduce them below.

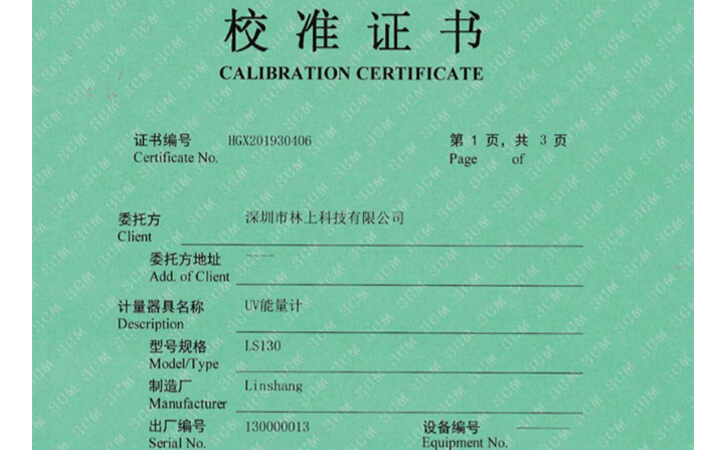

1. The calibration of the UV Integrator needs to be sent back to the manufacturer.

UV instrument data will have data attenuation, so it is recommended that the UV energy meter calibration can be sent back to the factory for calibration, or sent to the National Metrology Institute for testing. However, it is generally recommended that the user return the factory calibration, because the factory calibration, if the data is attenuated, the manufacturer can adjust the standard value back to the metrology inspection, only know whether the data is qualified, if the data is not qualified, the metrology institute is There is no way to get back to the right value.

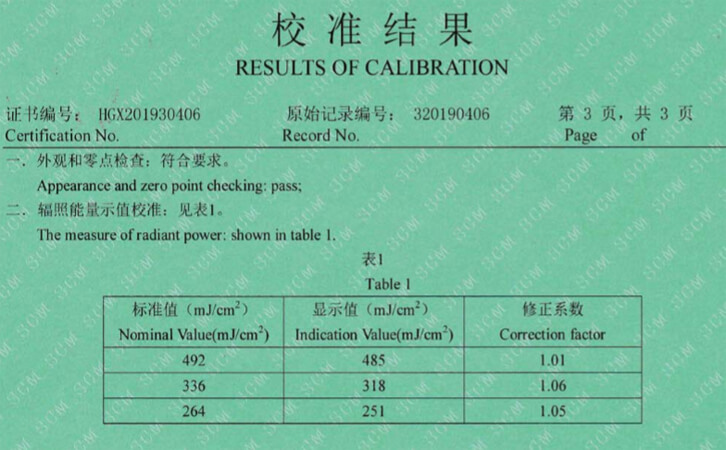

2. UV Integrator calibration is recommended once a year

The calibration of the UV Integrator is generally recommended once a year, and the calibration report issued by the Metrology Institute will also indicate the date of re-establishment, which is usually one year later. Please note that the metrology institute only issues a calibration report with the correction factor for the data, but the metrology institute will not calibrate the instrument. If calibration is required, it still needs to be sent to the manufacturer.

3. The cost of UV Integratorcalibration

The calibration fee for the UV energy meter to be sent to the metrology agency is about 130 dollars. If it is sent back to the factory for calibration, the cost is about 30 dollars. This fee does not include shipping charges. If you need to send it back to China for inspection, we will recalculate the shipping cost based on the returned address.