LED UV Curing Machines and UV LED Energy Meter

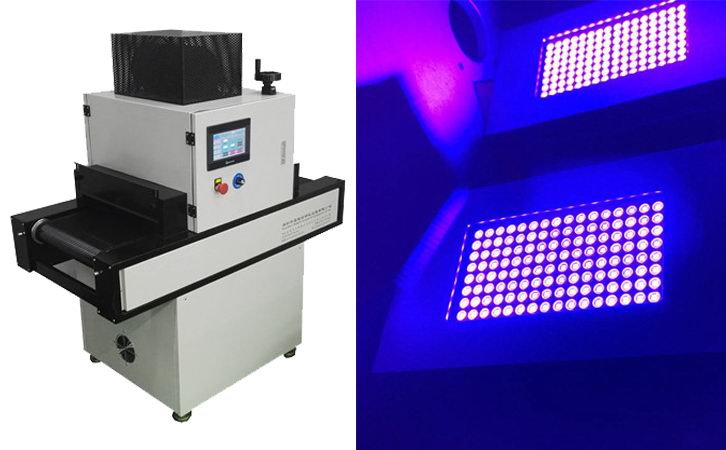

In industrial production, reliable, stable and shorter curing time is an important indicator. LED UV curing machine has many advantages over traditional mercury lamp UV curing machine: LED UV curing machine has no heat radiation and low energy consumption. Environmental protection, no pollution, simple installation and space saving, more importantly, the long service life of LED UV curing machine can reduce the input and use cost for customers.

1. Knowledge about LED UV curing machines

In recent years, LED UV curing machines have gradually replaced traditional mercury lamp UV curing machines in many applications and the market scale has expanded rapidly. The report shows that in 2016, the market size of China's LED UV curing machine has reached 530 million yuan, an increase of 26.5%.

The curing effect of the LED UV curing machine is determined by the absorption rate of the photoinitiator material. For most photoinitiator materials, the wavelength is shorter than 405nm for higher absorption, so LED UV curing machines often require wavelengths of at least 405nm. Basically, the shorter the wavelength, the higher the absorption rate. From this point of view, the LED UV curing machine used for curing should use short-wavelength LEDs as much as possible, but due to technical limitations, the shorter the wavelength of the LED, the lower the luminous efficiency (the lower the light intensity), resulting in a longer practical use. Wavelength UV-LEDs may cure better.

LED UV curing machine can directly convert electrical energy into UV light, and emits single-band ultraviolet light. The light energy is highly concentrated in a specific ultraviolet light band. Currently, the relatively mature applications in the market are 365nm, 385nm, 395nm and other bands.

In 2016, the Chinese market for LED UV curing machines at 365nm, 395nm, 385nm and other bands accounted for 29.2%, 48.3%, 8.2%, and 14.3%, respectively.

2. LED UV curing machines light source ultraviolet energy measurement

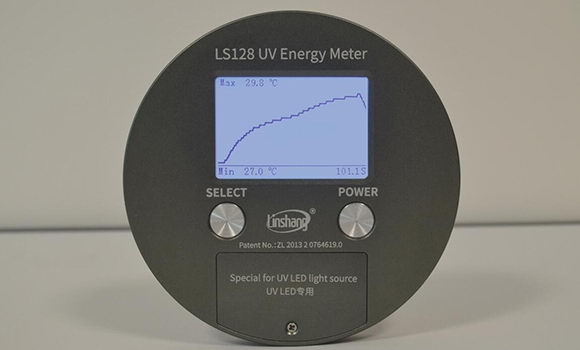

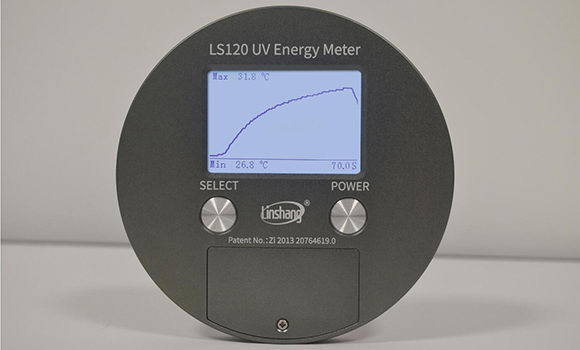

Some people would say that the ultraviolet energy measured by the energy meter is inaccurate. The reason is that they measure the UV LED light source using energy meter that dedicated for high pressure merycury lamps. The spectral response of the LED light source and high pressure mercury lamps are different. If you need to choose an UV energy meter, you need to know the types of the light source. Linshang Technology LS128 and LS131 UV LED energy meters are specifically designed to measure the ultraviolet intensity and energy of UV LED light sources in the 365-405 nm range. Linshang LED energy meter also provide PC software and test reports can be printed.

Linshang LED energy meter

● Response range: 340-420nm, calibrated at 395nm LED

● UV intensity measuring range: 0 - 40000 mW/cm²

● Measure energy, power and temperature, provide PC software to export the data

● Response range: 340-420nm, calibrated at 395nm LED

● UV intensity measuring range: 0 - 40000 mW/cm²

● Measure UV energy and power (intensity), provide PC software to export the data

● Test UV LED light sources

● Spectral response range: 340nm-420nm, calibrated at 395nm light sources

● Long term for high temperature resistance

Linshang mercury lamp energy meter

● Spectral response range: 315nm-400nm, λp = 365nm

● UV power (intensity) measuring range: 0 - 2000 mW/cm²

● Measure energy, power and temperature, provide PC software to export the data

● Spectral response range: 315nm-400nm, λp = 365nm

● UV power (intensity) measuring range: 0-2000 mW/cm²

● Measure UV energy and power (intensity), provide PC software to export the data

● Test high pressure mercury lamp

● Spectral response range: 315nm-400nm, λp = 365nm

● Long term for high temperature resistance