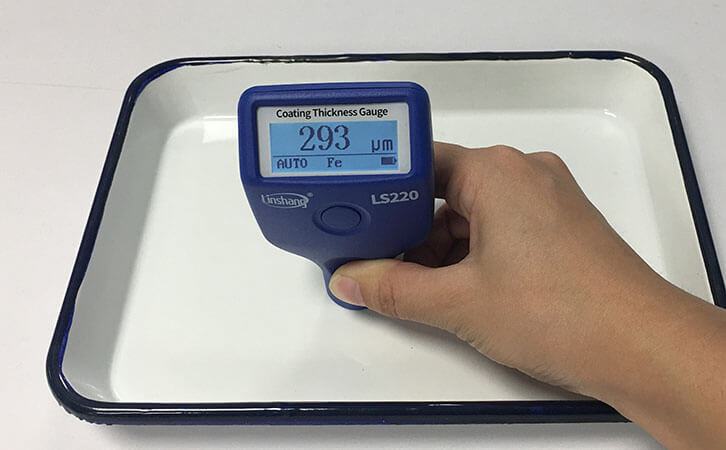

Use Magnetic Thickness Gauge to Measure Enamel Coating Thickness

The enamel protective layer can be seen everywhere in life and is widely used, but not all enamel protective layers have good anti-corrosion performance. It is necessary to strictly control the protective layer coating thickness. The magnetic thickness gauge is aimed at this. The magnetic thickness gauge is a thickness measurement tool for real-time monitoring of properties.

From the appearance evaluation, the enamel protective layer is very smooth. There is no exposed metal in any part and no unevenness anywhere. These factors are also the most basic quality requirements that the manufacturer must guarantee. The reason why the enamel protective layer acts as protective clothing is that it is not a wearable metal material, but is made of natural minerals such as feldspar and fluorite. It is not only wear-resistant, pressure-resistant, non-toxic and tasteless. There is no harm to the human body and the water tank can be cleaned and sanitized. There is no problem in long-term use. This also caters to the property that the magnetic thickness gauge is suitable for measuring the thickness of non-magnetic cover layer on magnetic metal substrate.

Contemporary people are most concerned about choosing enamel protective layer products: What are the most critical factors affecting the protective effect of enamel protective layer? It is undoubtedly the coating thickness of the enamel protective layer.

The following are brief criteria for testing enamel protection: The thickness should be uniform with the magnetic thickness gauge not less than 0.15mm and not more than 0.5mm

Too thick enamel protective layer affects the overall performance, easy to leak and detach. The smoothness of the surface is far from sufficient and it will be very easy to crack during transportation and transfer. If the thickness of the enamel protective layer is too thin, the internal metal materials will be exposed, which will not only fail to function as a "protective clothing", but also cause excessive loss. In general, the thickness of a high-quality enamel protective layer is controlled between 0.15 mm and 0.5 mm, which can possess some excellent properties.

In general, this standard thickness of enamel protective layer is the true "protective clothing" of metal materials.

It is precisely because the enamel protective layer is related to the safety of the internal metal materials. Therefore, manufacturers producing enamel protective layers always pay special attention to the coating thickness and often use professional and accurate magnetic thickness gauges to monitor. The principle of the magnetic thickness gauge is relatively simple, that is, the relationship between electromagnetic force and tensile force is fully used. This test method is very convenient and the conditions required are relatively small.

Therefore, most people use magnetic thickness gauge for self-inspection or quality inspection. The magnetic thickness gauge developed by Linshang Technology is a measuring instrument specifically for such non-metallic coatings on metal substrates. It can respond sensitively in a short time, it can accurately evaluate the protection of the enamel protective layer.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge