UV Intensity Meter Used in Curing Industry

In the process of curing with a UV lamp, you may often encounter the phenomenon of incomplete curing and tackiness on the surface. How this situation is caused and how to prevent it, we will share it with you here.

1. Factors affecting UV curing

(1) The curing spectrum, that is, whether the light emitted by a light source such as a UV lamp is consistent with the absorption spectrum of the cured object. Commonly used curing lamps include 365nm high-pressure mercury lamps and 395nm UVLED light sources.

(2) Intensity refers to whether the intensity of the light emitted by the light source is sufficient to cause a photochemical reaction of the cured product. Due to the different performances and dosages of the internal photosensitizers in different cured products (UV coating ink, glue), the penetration of the main agent and the amount of the agent light are also different, so curing strength requirements are different.

(3) Curing speed. If the curing speed is too fast, the curing cannot be completed. If it is too slow, it will adversely affect the cured material. The curing speed varies with different cured materials.

2. UV curing lamp intensity detection

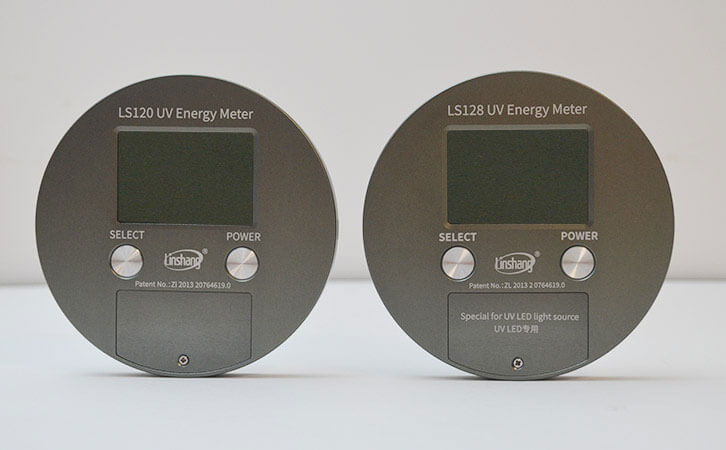

Linshang UV energy meter

As the electrode of the lamp tube is gradually decomposed, the inner wall of the lamp tube is deposited, the transparency and the transmittance of ultraviolet light are gradually weakened and the ideal curing effect cannot be achieved. Therefore, the lamp tube should be inspected regularly. This requires the use of a professional instrument UV intensity meter. It is recommended to use Linshang LS120 and LS128 uv intensity meters. These two UV intensity meters are respectively aimed at 365nm high-pressure mercury lamps and 395nm LED light sources. Both instruments use large-screen liquid crystal displays, which can simultaneously measure energy, power and temperature. The uv intensity meter can also display power and temperature curves, which more intuitively reflects the curing lamp during the curing process. It can also be connected to a computer and print a test report, which provides a basis for customers' regular testing.

Therefore, in order to avoid the defects caused by the intensity of the light source during the curing process, it is necessary to choose an UV intensity meter to regularly detect the light source.