Leather Dyeing Technology and Leather Surface Gloss Detection

With the improvement of living standards, people are demanding brighter varieties of leather products. Their performance requirements have become higher and higher in recent years. Consumers ’requirements for leather products have evolved from strong and practical to beautiful and fashionable; from single dark brown develops to colorful. This market demand makes the dyeing process appear more and more important. Dyeing is not only a process of leather production, but also has become an important way to give leather finished products value and personality.

Leather dyeing is a complex physical and chemical process. The penetration and binding process of dye molecules to leather fibers and the total effect of physical and chemical interactions. Throughout the dyeing process, adsorption, diffusion, penetration and fixation interact with each other and alternate. The leather dyeing process involves a wide range and many influencing factors. In addition to the various components that make up the dye liquor, the condition of the leather before dyeing, the control of pH, temperature, concentration and gloss during the dyeing process are important.

1. What are the methods of leather dyeing?

(1) Dip the product in a dye solution.

(2) Apply the dye solution to the product with a brush. The most commonly used black dye is aniline black.

(3) Supercritical staining.

(4) Ultrasonic staining.

(5) Electrochemical staining.

2. Leather dyes, methods and processes

Commonly used leather dyes are acid dyes, direct dyes, in addition to metal complex dyes, basic dyes, reactive dyes and so on. Direct dyes can be directly dyed on fibers after dissolving in water. The most critical step of dyeing is the color matching. In most cases, it is often necessary to mix several dyes together to obtain the desired dyeing effect, just like a palette. However, it is more complicated than color matching. Not only must the color mix be considered, but also many factors such as the dyeing rate, permeability and combination of leather. Therefore, the color matching during leather dyeing is a complicated process. At present, there are two methods of color matching: one is artificial color matching and the other is computer color matching. Most tanneries still dominate artificial color matching.

Dyeing methods generally include drum dyeing and spray dyeing. The drum dyeing method is used for batch dyeing of chrome tanned wet leather. It can be carried out in the same drum as retanning, neutralization and fatliquoring. This is currently the most commonly used method. The spraying method is suitable for dyeing the dried blank leather. Sometimes, the leather dyed by the drum is used as a supplementary dyeing method before painting, which can be sprayed by machine or manually.

3. Leather gloss detection

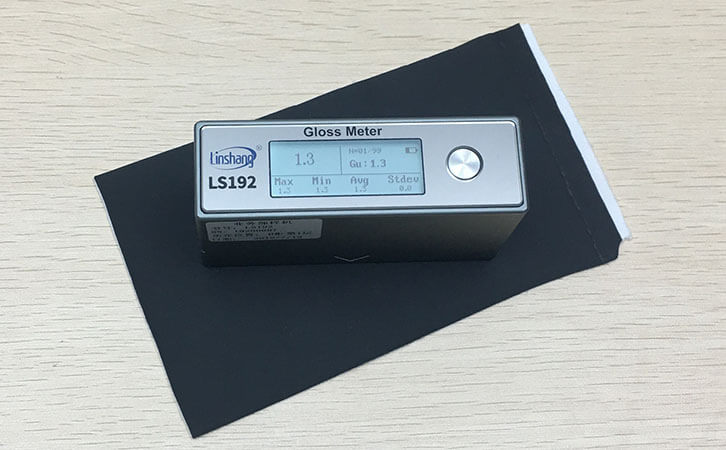

For leather gloss test, we can use Linshang surface gloss meter LS192. Linshang surface gloss meter LS192 is the first Chinese gloss testing equipment that can be compared with German surface gloss meter BYK . Linshang surface gloss meter has following asvantages:

● Various measurement modes of the instrument, automatic measurement and manual measurement.

● Real-time measurement.

● It can display real-time value, maximum value, minimum value, average value, standard devition values. The smaller the standard deviation, the more uniform of the object surface gloss.

● Ultra-small design, take it with you wherever you go.

● The number of storage groups can be set by yourself. A maximum of 99 sets of data can be measured.

● The instrument meets the national metrological verification regulations JJG 696 level surface gloss meter standard.

● Connect to the computer, expand more functions and output professional reports in real time.

It is the best choice to measure the surface glossiness of leather with Linshang surface gloss meter LS192!