Use Zinc Plating Thickness Tester to Measure Galvanized Layer Thickness

In the metal coating processing industry, in order to evaluate the galvanized coating thickness, a zinc plating thickness tester is often used. This article mainly describes the working principle, measuremen range of zinc plating thickness tester and how to measure the galvanized coating thickness.

1. What is the maximum measurement range of zinc plating thickness tester?

Different zinc plating thickness testers have different measurement ranges due to different measuring principles. Generally speaking, the zinc plating thickness tester unit on the market is μm. The measuring range of different brands and models ranges from 0 to 5000 μm.

Many zinc plating thickness testers use magnetic thickness measurement and eddy current thickness measurement principles.

Magnetic thickness measurement method: The magnetic zinc plating thickness tester is suitable for non-magnetic layer thickness measurement on magnetically permeable metal substrates. For example, the substrate is steel \ iron \ silver \ nickel and the surface coating is zinc plating, copper plating, chrome plating, rubber, paint, etc.

Eddy current thickness measurement method: The eddy current zinc plating thickness tester is suitable for non-conductive layer thickness measurement on conductive metal substrates. For example, the substrate is copper, aluminum, zinc, tin and the surface is covered with enamel, rubber, paint, plastic, etc.

Compared with the two, the measurement accuracy of the magnetic thickness method will be higher. Users can choose different zinc plating thickness testers according to measurement needs. Magnetic thickness gauges and eddy current thickness gauges generally measure thicknesses of 0-5 mm. These instruments are divided into integrated type and separated type. Thicker dense materials need to be measured with an ultrasonic thickness gauge. Its measured thickness can reach 0.7-250 mm.

2. How to measure the thickness of galvanized layer?

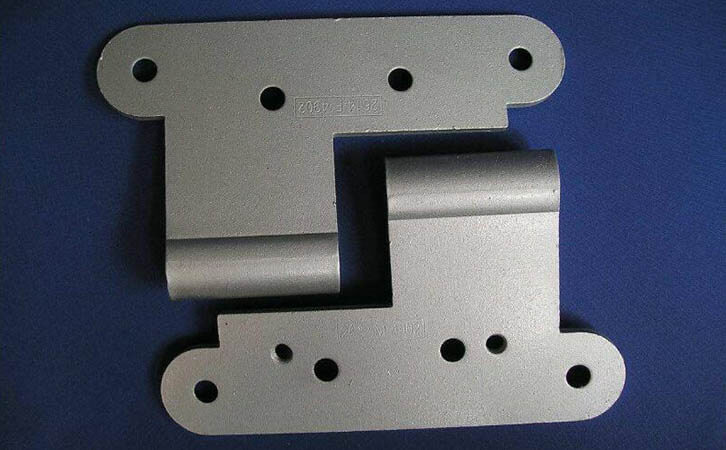

For zinc plating thickness testers, depending on the applicable measuring principle, the coating range suitable for different measurement methods is different. And the accuracy of the measurement is also different. Three zinc plating thickness testers independently developed by Linshang Technology can be used to measure the galvanized layer thickness. The accuracy is consistent with the accuracy of the international brand Q-nix. LS221 and LS223 two zinc plating thickness testers are externally connected, suitable for testing coating thickness in narrow test environments. We can place the probe on the measured coating thickness and hold the host with another hand.

For example, this zinc plating thickness tester cannot be used if the surface of the plastic product is galvanized. If the surface of the iron plate is galvanized, you can use this zinc plating thickness tester to measure. If you need to measure the galvanized layer (or other coatings) on the surface of plastics and wooden boards, the ultrasonic thickness measurement method will be used. The ultrasonic thickness gauge are generally expensive.

Taken together, the conventional iron-based zinc plating thickness tester can measure the galvanized layer on the surface of magnetic materials.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge