Glossmeters | Measuring Gloss on Various Surfaces

I. Desktop and Portable Glossmeter

Glossmeter is a glossiness measurement device used to measure the specular reflection gloss of the material surface.

1. What is a glossmeter?

Glossmeter (also called gloss tester) is a glossiness measurement device used to measure the specular gloss of the surface of the material. The gloss of the product is an important parameter that needs to be controlled during the production process.

For example, ultraviolet light is used to cure ink or paint during the production of food packaging. Once the product gloss is found to be reduced, it is likely to be caused by incomplete curing. In addition to affecting the consumer experience, such bad products may contaminate food and affect human health. Therefore, using a glossmeter to monitor gloss in the production process can find problems as soon as possible, ensure the production process and product quality and save the cost of recalling defective products.

2. Features of Desktop Glossmeter Desktop Glossmeter

Desktop glossmeters are generally larger in size, with a micro-hole design, with the test hole facing upwards. The sample to be tested should be placed above the test table during measurement.

It is mainly used for the mirror gloss measurement of curved surfaces and small objects such as electroplating, mobile phone accessories, hardware parts and so on.

Commonly used in laboratories and other occasions, the price of desktop glossmeter is about 4200 dollars.

3. Features of ortable Glossmeter

The portable glossmeter is compact and can be held with one hand. The test hole is under the host. When measuring, the glossmeter should be closely attached to the surface of the sample to be measured.

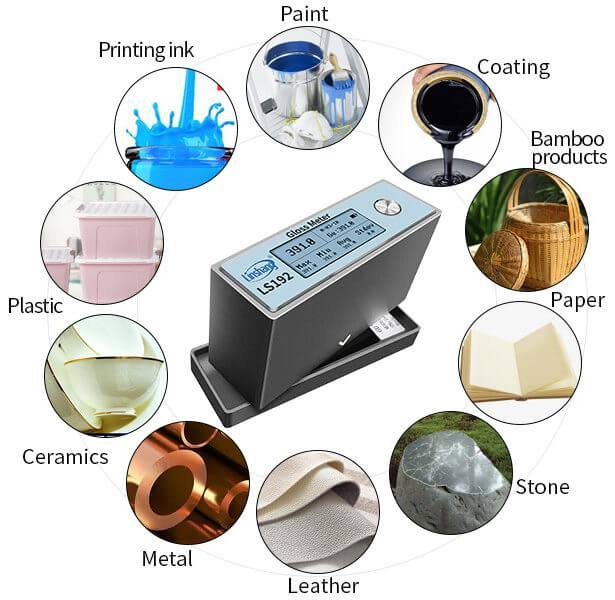

Portable gloss meter is mainly used to measure the mirror gloss of various flat products such as metal, paper, plastic, marble, paint, ceramics, etc.

Not only suitable for carrying out, but also can be used on the operation table. The price of the portable glossmeter generally does not exceed 5,000 RMB.

II. Linshang and BYK Glossmeter

1. Comparison of main parameters of Linshang and BYK glossmeters

| Model | Measuring Angle | Repeatability | Reproducibility | Measuring Aperture | Price |

|---|---|---|---|---|---|

| BYK glossmeter micro-gloss | 20 ° / 60 ° / 85 ° | 0.2GU, 0.2% | 0.5GU, 0.5% | 10 * 10mm (20 °) 9 * 15mm (60 °) 5 * 38mm (85 °) |

US$3500+ |

| BYK glossmeter micro-tri-gloss | 60 ° | 0.2GU, 0.2% | 0.5GU, 0.5% | 9 * 15mm | US$2100+ |

| LS192 glossmeter | 60 ° | 0.2GU, 0.2% | 0.5GU, 0.5% | 9 * 15mm | US$255 |

2. BYK and Linshang glossmeter measuring gloss on various surfaces

III. How to Measure Gloss Using a Portable Glossmeter?

1. Measuring principle of glossmeter

The glossmeter measures the gloss of the sample using the principle of light reflection. The gloss value displayed by the instrument is a relative value calculated by referring to black glass with a gloss value of 100GU (projecting a beam of light onto an ideal polished and refracted on black glass with a rate of 1.567, this plane mirrors the light beam and defines the gloss value at this time as 100.0GU, where GU is the gloss unit).

2. The LS192 glossmeter measures the gloss of the metal surface

We take the Linshang LS192 glossmeter as an example to introduce in detail how to use the glossmeter to measure the gloss of the metal surface and print the test report through the computer software. Materials to be measured: 1 piece of flat metal product to be tested, 1set of LS192 glossmeter (1 piece of standard base with standard plate, 1 piece of professional lens cleaning cloth, 1 piece of USB data cable, etc.), 1 computer

(1) Self-check and self-calibration

First make sure that the LS192 glossmeter is in the base, press the power button to turn on. The base of the instrument is equipped with a standard board, the test data is the relative value obtained based on the gloss of the standard board, so the use of the damaged standard board will affect the measurement accuracy. During the self-test and self-calibration process, the user will be required to wipe the standard plate with a professional lens cleaning cloth to ensure the accuracy of the glossmeter test data.

(2) Measuring and saving data

After entering the measurement interface, remove the glossmeter from the base. The bottom is close to the metal product to be measured. You can see that the glossmeter will immediately display the real-time gloss value. Short press the power button to save the current test value and change the measurement position. After recording multiple sets of data, as shown on the right, you can see that the instrument automatically counted the maximum, minimum, average and standard deviation of historical data.

(3) Export test report

Connect the LS192 glossmeter to the computer via the USB data cable (the computer software with LS192 installed), open the software, you can read the test data and export the test report, as shown on the right. In the software, you can also set the upper limit and lower limit of the test data. So the user can know whether the data exceeds the qualified range.

IV. Linshang Gloss Meter

2. Measuring angle is 60 degree.

3. Suitable for surface gloss detection of high gloss items such as metal and plating materials.

2. Measuring angle is 60 degree.

3. Suitable for surface gloss test of low gloss materials such as paints, coatings and paper.