Gloss Measurement of Waterborne Epoxy Coatings

Portable gloss meter is developed for measuring the surface specular gloss of the object such as paint, coating, marble, furniture, leather, etc. Waterborne epoxy coating is a commonly used floor coating material. Different quality water-based epoxy coatings and construction processes can cause differences in surface gloss. In order to control the quality of waterborne epoxy coatings, we can measure the gloss by portable gloss meter.

1. Factors influencing the gloss of waterborne epoxy coatings

Waterborne epoxy coatings have the advantages of high hardness, strong adhesion and good chemical resistance. They are widely used in anticorrosive coatings and industrial floor coatings. However, different waterborne epoxy formulations and construction processes can cause differences in gloss of waterborne epoxy paint films. The main causes are listed as following:

(1) Production formula of water-based epoxy floor

Waterborne epoxy coatings are made by mixing standard liquid epoxy resin, water, defoamer, wetting agent and waterborne epoxy curing agent. Different formulations will cause a certain difference in gloss of waterborne epoxy paint films.

(2) Coating thickness and uniformity

The uniformity of the coating film mixing and the application coating thickness will cause differences in gloss of the water-based epoxy paint film.

(3) Flatness of substrate

If the floor is not polished uniformly and there are holes, it will also affect the gloss of the water-based epoxy paint film.

2. How to measure the gloss of waterborne epoxy coatings?

(1) Gloss measurement of waterborne epoxy coatings

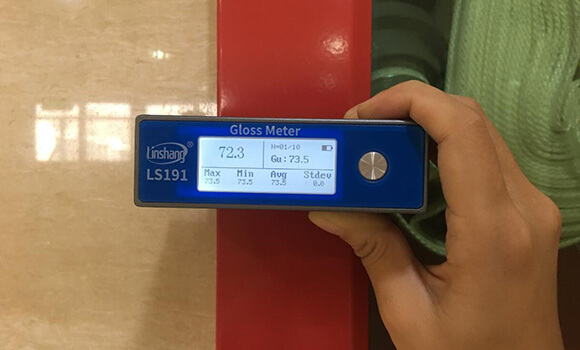

Linshang portable gloss meter can achieve accurate surface gloss measurement of water-based epoxy paint films. Gloss is a visual property of an object. The more light that can be reflected from the object surface, the more pronounced the gloss and the higher the gloss. Judging the object surface gloss with the naked eye depends entirely on experience, but to truly evaluate the uniformity of the gloss, you need to use a professional portable gloss meter to measure it.

(2) Choose the correct angle of gloss measurement for waterborne epoxy coatings

The gloss measured by the portable gloss meters is related to the angle of incidence of light. So when measuring the same material, the measurement data of the portable gloss meter angle is different. 60 degrees is the most common measurement angle of portable gloss meter. Any gloss material can be measured using the standard measurement angle of 60 degrees. High gloss, medium gloss and low gloss are also divided according to the measured gloss data of the 60 degree portable gloss meter.

3. Best glossmeter in China

Linshang gloss measuring instruments are all independently developed and produced. The universal 60 ° measurement angle is suitable for the surface gloss measurement of low and medium gloss materials. It is also more suitable for gloss measurement of waterborne epoxy coatings.

For the measurement and verification of glossiness measuring instruments, the country has clear regulations. The standard is "JJG696-2015 Specular Gloss Meters and Gloss Plates". All indicators of the Linshang gloss measuring instrument have met the requirementsof the first-class working machine in the national metrological verification regulations.

The portable gloss meter produced by Linshang has high cost effective performance compared with other Chinese portable gloss meters. It's perfect to use it to check the specific gloss of waterborne epoxy coatings!