Curtain Color Quality Control

In order to match the overall style of the room, it is necessary to choose a suitable curtain style. If the color deviation of the curtain fabric appears, I believe it is a very bad thing for people who are going to live in a new home. To avoid this problem, curtain manufacturers must control the color quality of curtains when producing the product. A professional portable colorimeter can help them.

I. How important is the curtain color difference?

If you want suitable light and color style in the room, then how to choose curtains is the top priority. In order to achieve the ideal effect in your mind, some owners and friends will order curtains. However, in the choice of fabrics and the specific production process, the customized curtains are prone to have color difference. Curtains with color difference will spoil the overall beauty of the room. Now, we can see the importance of color quality control using portable colorimeter.

II. Why does the curtain have color difference?

Curtains are made of materials such as cloth, hemp, yarn, aluminum, wood, metal, etc. What we are mainly studying today is the cause of the curtain fabrics color difference.

The reasons for the color difference of curtain fabrics are mainly divided into the color difference of natural materials and the color difference caused by the production process.

1. Curtain color difference caused by natural materials

Not only exists in the curtain industry, but the "color difference" of many natural materials is also common in the furniture, ceramic tile and floor industries. For example: if the same wallpaper uses natural materials, such as straw, paper, diatomaceous earth, cloth pulp fiber, etc.The color difference caused by the different natural materials itself, this situation can not be avoided. The natural beauty of natural materials is not a problem of product quality.

In addition to the color difference of natural materials, the color difference caused by the production process can often be minimized.

2. Curtain color difference caused by production process

The production of curtain fabrics needs to go through multiple processes, from the original color fabrics, through desizing, desizing, dyeing and other processes, to finally form the color of the finished fabric. Due to changes in temperature and humidity during the production process and different batches of colorant formula, the error will cause the deviation of the curtain fabric color. Due to the influence of the thickness, density and water absorption of curtain fabrics, the adhesion of printing and dyeing is also slightly different, which can also lead to chromatic aberration of the fabric.

III. Portable colorimeter control curtain color quality

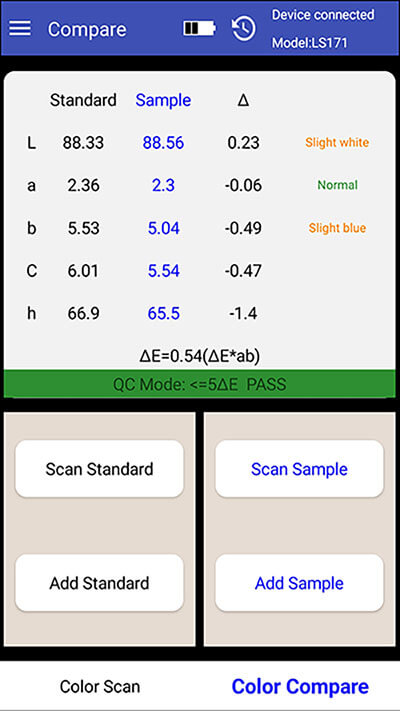

In order to deal with the color difference of curtain fabrics, we need to use a color comparison tool-portable colorimeter. The main function of the portable colorimeter is to make the measured color difference data-based and operable.

According to the color presentation of curtains, we know that the color of an object depends on the object's selective absorption of incident light. If the absorption spectrum is different, then the color of the presented object will be different. The portable colorimeter uses this principle to detect the reflected light energy of the sample and compare the spectral reflectance of the sample. According to the relevant formula, the tristimulus value xyz of the sample is calculated. Then, through the conversion of the color space, the CIE Lab value is obtained.

By measuring the Lab values of the test sample, Linshang portable colorimeter can match three cloest color codes from the selected color chart such as Pantone color chart. Then you can use the selected color code matched by the portable colorimeter as the standard color. By controlling the sample color, the sample can be mass produced.