Color Measurement of Packaging

1. Why packaging color quality control is important?

We live in a colorful world, because various products have different colors, which can be accurately recognized by people. Data analysis shows that when people observe objects, the initial visual perception mainly depends on different colors, color perception accounts for 80%, and the product's shape only accounts for 20%; After two minutes. Color perception accounts for 60% and shape accounts for 40%; After five minutes, the color impression continues in the human visual memory.

Whenever people are shopping for products, colorful products will quickly attract our attention and stand out in the colorful product display area. The color of the product packaging can make the product distinct from the visual characteristics of other products. It is more attractive to entice consumers, thus causing consumers to associate. To a certain extent, it can influence the consumer'simpression of the product and directly stimulate the purchaser's consumption desire.

Therefore, more and more shopping malls have begun to pay attention to the use of color in packaging and achieve the purpose of establishing a product image through reasonable color matching. The color selected here should be easy to identify and remember, or use a simple color combination to express the specific quality of the product.

2. Packaging color measurement methods

Exquisite packaging is a simple and effective means of product promotion. Therefore, the quality of packaging and printing is becoming more and more important in the production process. Especially large food processing companies and beverage manufacturers pay great attention to product packaging. Color management, so how do they detect packaging colors?

With the rapid development in the field of color inspection, there are more and more methods for assessing the color of packaging. Small and medium-sized enterprises with low color requirements often use visual methods. For paint and coating manufacturers, in order to accurately assess the blending ratio of the pigment will accurately measure the difference value through the handheld colorimeter. In more industries, in order to pursue the perfect packaging color of products, it will combine the visual method and the handheld colorimeter detection method.

Visual method:

Directly evaluate the difference of packaging colors through the human eye. The results of this method are suitable for people's observation habits. However, because the visual method is affected by the size and shape of the packaging sample, the light source conditions, the surrounding color environment, the viewing angle and the observer's own factors. In order to ensure the accuracy of the visual assessment results as often as possible, handheld colorimeter will be used.

Measuring packaging color using handheld colorimeter:

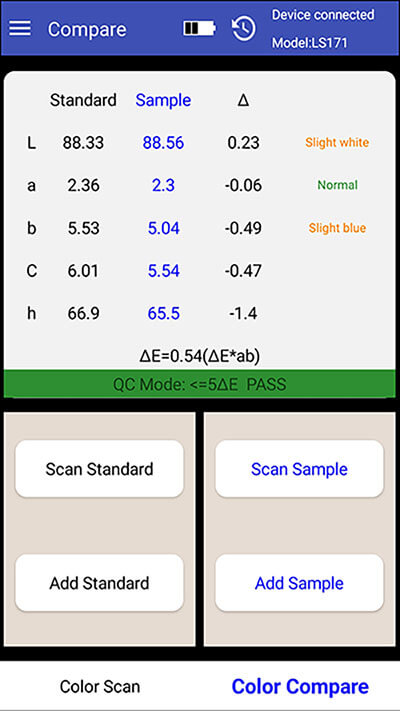

Handheld colorimeter is an optical detection instrument that simulates the color viewing process of human eyes. According to the principle of CIE color space, the degree of difference in packaging color can be expressed numerically. According to △ E and △ Lab. The value can accurately determine the color of the packaging, further adjust the production process and control the color quality of packaging production.

For example, when using LS171 handheld colorimeter to measure the packaging color, we can select the color chart we need first, such as Pantone color chart. Then place the color measurement tool on the test sample, the meter will match three cloest color codes from your selected color chart. Next time when you want to use this color, it means that you can use the matched color code.

In the actual packaging color detection process, there will also be a phenomenon that the visual detection does not match the detection result of the handheld colorimeter, so it will be compared through two methods and combined to evaluate each other.