Color measurement in food industry

Products in food industry can be in different color, shade, category and purity. Color difference is an important quality attribute of food appearance which being tested to inspect quality. The food colorimeter plays a key role in this link, so this article will introduce it to you.

What is food colorimeter?

The food color difference meter can provide a complete and comprehensive color solution for the food and beverage industry in the whole process of raw materials, processing, finished products and final products. Compared with the visual method, it is more accurate and convenient to use an instrument to measure the color of the material to judge its quality.

Food colorimeter applications

The surface of products in food industry is usually uneven and filled with a large number of textures, which adds a lot of difficulty to color detection. When multiple samples or large-volume foods need to be tested at the same time, due to the limitation of equipment style and size, the measurement will be inaccurate and the color measurement will not be successful. The food colorimeter can be used for testing in the following food industries:

1. Flour and rice quality inspection industry

At present, people have higher and higher requirements for the quality of flour. Whiteness is the sensory impression of the material color by the naked eye, and is characterized by high brightness and low chroma. The whiteness value measured by the traditional digital whiteness meter cannot express the color of the flour well, because the whiteness value makes the color of the flour not necessarily very good when viewed with the naked eye, and the whiteness cannot be quantitatively analyzed. LS176B spectrophotometer with bluetooth has 3 whiteness measurement indicators: whiteness -98, Gauz whiteness, and Hunter whiteness, and the whiteness value of the material can be obtained by one-click measurement. By using the food colorimeter, the color difference between different flour samples can be accurately compared, and the quality of the flour color can be judged accordingly.

2. Vegetable oil quality testing industry

There are many indicators for testing vegetable oils in the market, such as acid value, iodine value, peroxide value, etc. Oil color is one of the simpler evaluation criteria. The different colors of vegetable oils are caused by various pigment substances in them. In addition, the deterioration of oil quality and rancidity of oil will also lead to darker oil color. Therefore, using the food colorimeter to measure the color of the oil can help you understand the purity, processing technology and refining degree of the oil, and at the same time judge whether it has deteriorated. LS171 colorimeter adopts D/8 optical structure, built-in multi-color card, equipped with mobile phone APP, can save multiple standard colors. The instrument is used with a cuvette, which is more convenient to detect liquid food. One thing to note is that when detecting transparent and translucent liquids, the material needs to be shielded from light.

3. Meat product quality inspection industry

The freshness of raw meat has a great impact on food safety and human health, so it is of practical significance to quickly test the freshness of raw meat. Meat freshness inspection is mainly carried out from the aspects of sensory, spoilage decomposition products and bacterial contamination. The operation of these detection indicators is very complicated, and it is difficult to control factors, while the food colorimeter method is fast, simple to operate, easy to control the conditions, and can regularly reflect the freshness of meat. LS175 colorimeter has the characteristics of large aperture, can cover a large area of the material to be measured, and has the advantages of high precision, short measurement time and good repeatability.

Color judgment by color difference meter

In the process of using the food colorimeter, we need to judge the color cast of the product based on measurement results. The corresponding values are as follows:

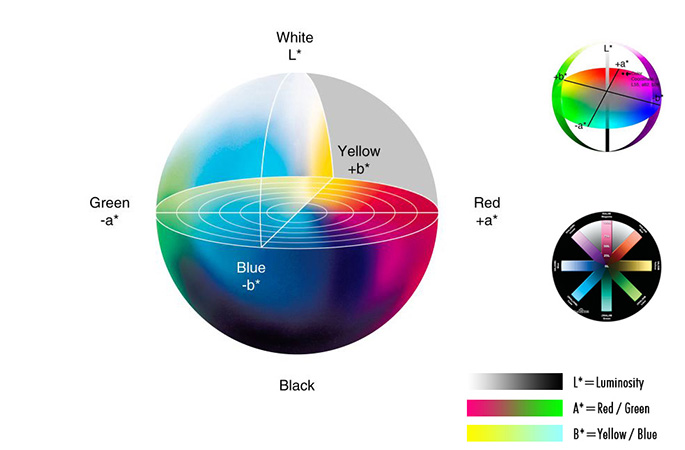

L* values (also called value) indicate degree of lightness from black to white (range = 0 – 100).

The chromaticity index a* is the red-green axis. Negative a* is green and positive a* is red. Both a* and b* values range from -127 to +127.

The chromaticity index b* is the yellow-blue axis. Negative b* is blue, positive b* is yellow.

These values can be used to calculate hue and chroma (also called saturation). Hue is what we usually call color. So reds, greens, blues, etc. are actually hues rather than simple colors. Color is more complex and includes not only hue but also variations in brightness and intensity. Chroma refers to the intensity of the hue. Lightness (L*) changes from top to bottom, hue changes as you move around the center, and chroma changes as you move from the center out.

All colors can be represented by the three values of L*a*b*, the difference between the sample and the standard is represented by ΔL*Δa*Δb*; ΔE* represents the total color difference.

Color is one of the appearance indicators of food, and it plays a key role in the process of food quality judgment and inspection. When choosing a food colorimeter, you should pay attention to choosing the corresponding food field, so that the function of the food colorimeter can be used to the best.