Color Management in Printing Industry

Appearance is an important factor affecting product quality, especially color. The strongest first human visual perception is the color of the product. Good products with beautiful colors can stimulate people's purchasing desire. As more and more designers begin to pursue color matching, the "fresh" term color difference has gradually entered people's field of vision. Just imagine, if the packaging colors of the same product in different batches are inconsistent, will customers have doubts about the quality of the product? This problem can be solved quickly with the help of portable color meter with color data storage function.

I. Causes of packaging bag color difference

In the printing process, color difference of packaging bags are prone to occur and there are many reasons for color difference. Below we briefly list a few common reasons:

1. Printing pressure

If the printing pressure is insufficient, the ink layer is prone to unevenness. Therefore, when printing, it is best to ensure that the raw materials and printing plates are relatively flat.

2. The color of the raw material

If the transparency of the film used each time is different, the color produced after adding different colors will also be different. Therefore, it is best to use the same transparency film.

3. Surface treatment technology

If it is a piece of film, after a series of treatments such as laminating, glazing, oiling and printing, the surface of the product will undergo chemical changes (UV oil and varnishing will cause chemical changes to the printed ink layer) and physical changes (after processing, the surface of the object adds specular reflection).

The packaging bag has color difference and can be divided into two situations. One situation is the color difference between the same batch of products, the other situation is the color difference between the standard product and the sample. The color of the produced packaging bag does not meet the customer's requirements. At present, many printing companies do not implement standardized management when storing samples. After the packaging bag was produced, it was found that the standard product sent by the customer was missing. Just think that the color is about the same from your own memory. In this way, the color of the product is of course unqualified. After being sent to the customer, it will not only be returned by the customer, but also affect the cooperative relationship with the customer. It can be said that the gain is more than the loss.

II. Color management in printing industry

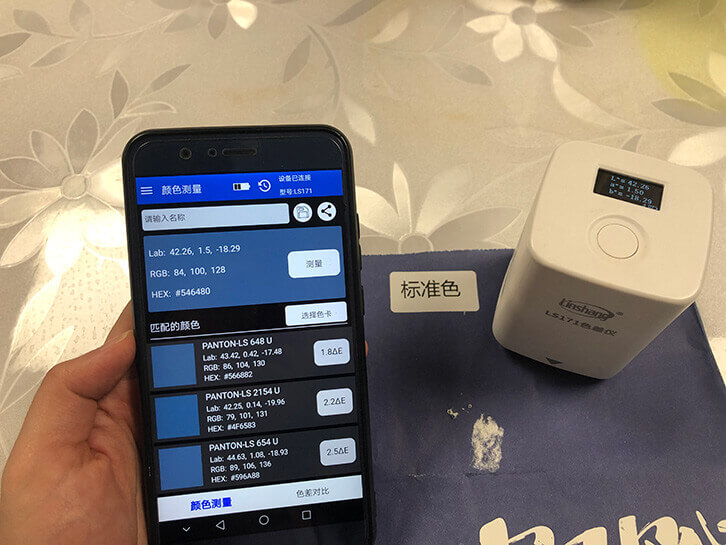

Most formal enterprises use colorimeters to measure the color difference of packaging bags. Linshang LS171 color difference meter is a portable instrument with D/8°optical structure. When we are measuring, we can first use the color meter to measure the color of the standard material and save the color of the standard material to the colorimeter mobile App. When measuring the sample next time, you can directly add the color of the standard material to the color of the sample for comparison. For detailed operation, you can watch the following video:

As shown in the above video, simple operations can solve the problem of corporate color management. Why not do it? This portable color meter also has a QC testing function and the threshold can be set to 0-50. In the video, we set the threshold value to 3. If the ΔE value is less than 3, the color difference meter will judge the product as qualified. If it is greater than 3, it will be judged as unqualified. Through simple color contrast, the color difference of the product can be controlled. This color difference meter price is very low. It is not as good as action, come and consult!