Ambient Light Affect Gloss Checker

In order to ensure the accuracy of the gloss checker, it is necessary to maintain the stability of the gloss checker. If the external light changes drastically during the measurement, or the instrument's internal light source changes, it will cause a large deviation in the measurement result.

1. Gloss checker principle

Under the condition that the opening angle of the light source and the receiver is specified, the ratio of the reflected light flux of the sample in the specular reflection direction to the reflected light flux of the glass standard sample in the specular reflection direction. Set the specular gloss of the polished black glass with a refractive index of 1.567 as100 (gloss unit) at a geometric angle of 60 degrees. From the principle, we can see that the gloss checker is a comparative test quantity that needs to be compared with the standard board. The standard board is inaccurate and other measurement data will not be discussed. The standard board is susceptible to scratches and dust. The design of the gloss checker requires that the standard board be well protected.

2. Requirements of ambient light for gloss checker

Gloss checker is a precise optical instrument, its detection principle is that a certain light source illuminates the sample at a certain incident angle. The gloss measuring instrument receives the specular reflection light of the sample at the same reflection angle as the incident angle and reflects the light reflected by the specular surface of the sample. The ratio of the specular light reflected by the standard gloss plate under the same conditions indicates the result.

Therefore, the measurement of glossiness is inseparable from the light source. If the light source changes, then the luminous flux of the same object irradiated by different light sources changes. The measurement results will be very different. Therefore, in order to avoid the interference of external light sources as far as possible, the gloss checker generally needs to be close to the measured object surface. The standard board is a precision optical component. If stimulated by strong light, it will cause the standard board to change. Therefore, the standard board equipped with the gloss checker is a precision optical component. It must be properly stored and used, avoid bumping the work surface with sharp objects, and avoid exposing the standard board in strong light.

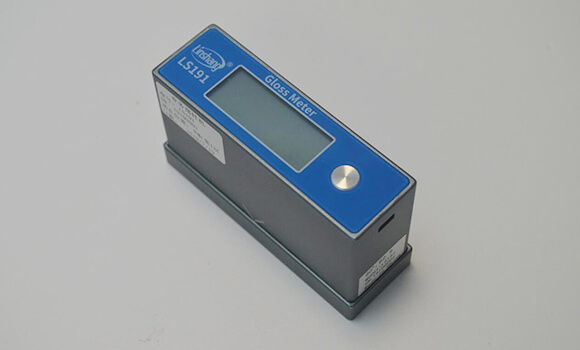

3. Linshang LS191 gloss checker

(1) LS191 gloss checker application

The LS191 gloss checker is a high-precision glossiness measurement device independently developed by Linshang Technology, which has independent intellectual property rights and conforms to the Chinese national standard GB / T9754. The gloss checker adopts a 60 ° universal angle to meet the requirements of the first-class working machine in the JJG696 standard.

The glossiness measurement range of LS191 portable gloss checker is 0-200GU, which is especially suitable for the gloss measurement of medium and low gloss type paints, inks, coatings, plastics, leather, ceramics, bamboo products, marble and other materials.

(2) How to use the gloss checker LS191?

First press the Power button to turn on the instrument. After the calibration is completed, the test interface is entered. The display interface can display the real-time value, maximum value, minimum value, average value, standard deviation deviation value, current recorded value and the number of measurements and statistics. After the test, close the instrument to the base of the standard board. The instrument will automatically shut down in 15 seconds.

For gloss checker LS191, there is no need to press the button during the test. As long as the instrument is placed on the tested material, the test data will be displayed immediately. Press the power button, you can record the current test data. The instrument automatically calculate the maximum, minimum, average and standard deviation. The smaller the standard deviation value, the more uniform the gloss of the material surface.