UV Energy Meter

As an UV measurement device supplier providing a fair price of UV energy meter for LED, mercury vapor lamp, curing and UV exposure machine, Linshang has developed different models of UV energy meters. According to the type of ultraviolet light source measured, the instruments can be divided into two categories, LS120, LS136 and LS138 for testing the energy and intensity of high-pressure mercury lamps, LS128 and LS137 for testing UV LED.

For more information on the similarities and differences of these UV energy meters and UV light meters which can also measure the energy values, please refer to the following article "UV Energy Meter Selection and FAQ".

LS120 Portable UV Energy Meter

Spectral response range: 315nm-400nm, λp = 365nm

The first UV energy meter has temperature and UV power curve

The first UV energy meter with real-time temperature and UV irradiance

The first UV energy meter can connect computer via USB and print the results

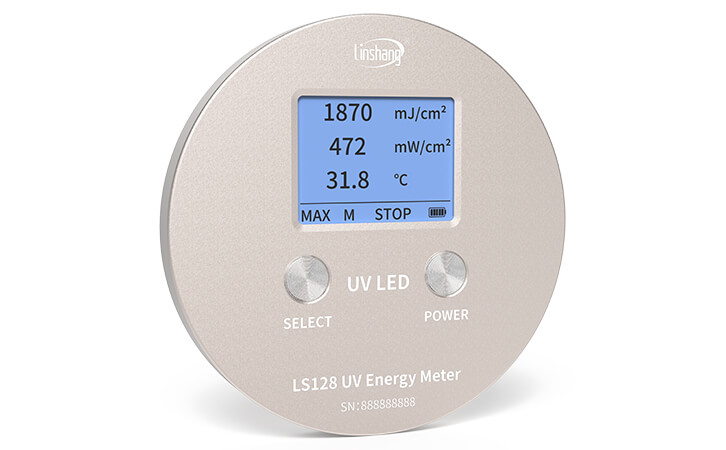

LS128 UV LED Energy Meter

The first UV Energy meter special for UV LED (365, 385, 395, 405nm, etc.)

The first UV Energy meter has the UV intensity measuring range of 40000mW/cm²

The first UV Energy meter for UV LED intensity and energy measurement

Measure energy, UV power and temperature, provide PC software to export the data

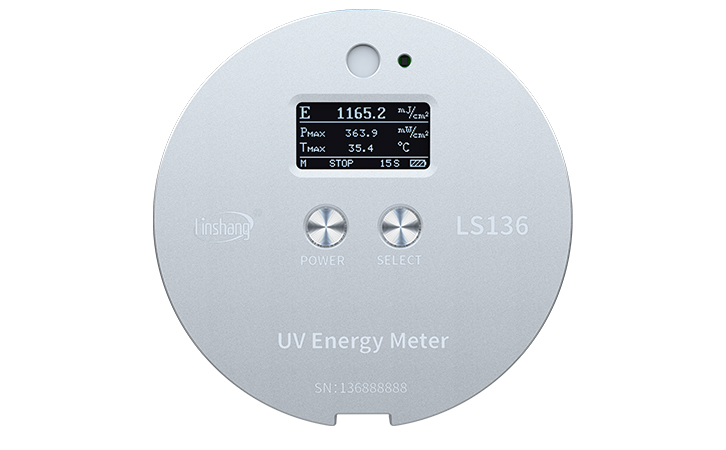

LS136 Economical UV Energy Meter

For high pressure mercury lamp, halogen lamp

Spectral response range: 315nm-400nm, λp = 365nm

Thickness of only 7.6mm, simple operation

Long-term for high temperature resistance

LS137 UV LED Energy Meter

Suitable for UV LED light sources

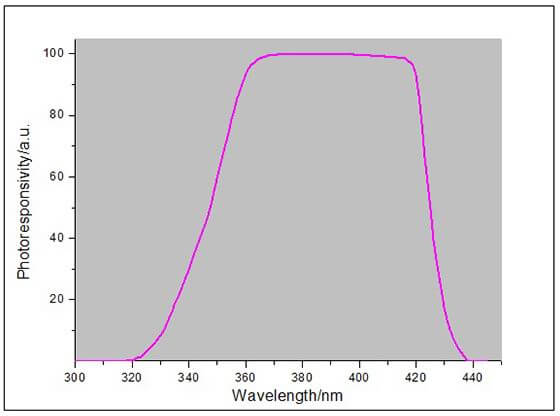

Response range: 340nm-420nm, calibrated at 395nm LED

7.6mm thickness , simple operation

Long-term for high temperature resistance

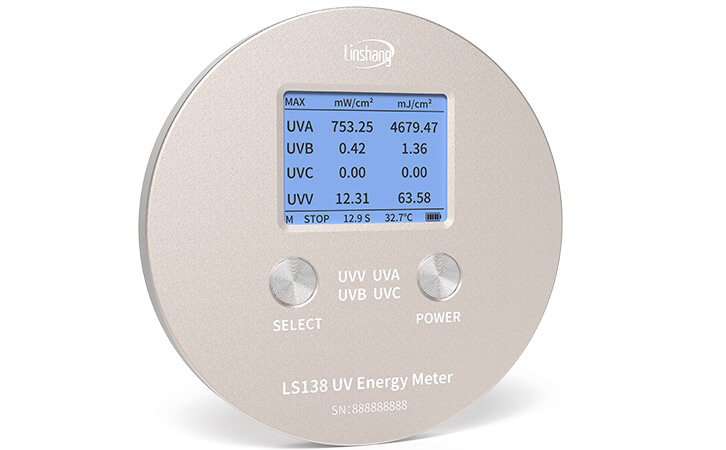

LS138 Four-channel UV Energy Meter

Simultaneously tests UVA, UVB, UVC, and UVV energy and intensity.

Monitor temperature and UV power in real time and display their test curves.

2048 times/second ultra-fast sampling for accurate measurement.

Includes PC software for easy report export and printing.

LS130 UV Energy Meter

UV energy meter special for high pressure mercury lamp

Spectral response range: 315nm-400nm, λp = 365nm

Can display real-time UV power, maximal power, energy and curing time

Measure UV energy and UV intensity, provide PC software to export the data