Coating Thickness Gauge

Linshang's coating thickness gauge, also named dry film thickness gauge, which can identify the substrate automatically. It can be used in various fields such as coating thickness measurement, plating thickness measurement, fireproof and anticorrosive coating thickness measurement, etc. The dual-use coating thickness gauge such as LS220H and LS221 are suitable for ferrous and non-ferrous substrates, LS225+F500 is special for ferrous substrates and LS225+N1500/N2000 is special for non-ferrous substrates.

Discover why Linshang’s models are rated as the best coating thickness gauges for industrial use, please read "Coating Thickness Gauge Selection and FAQ" and "Paint Thickness Gauge Selection and FAQ" for details or browse the FAQ at the bottom of this page.

LS220H Dry Film Thickness Gauge

Highly sensitive probe, 0.5s measuring interval.

Ferrous/Non ferrous thickness meter.

Dry film thickness measurement within 5000μm.

High accuracy and good repeatability.

LS221 Split-Type Coating Thickness Gauge

Measuring range: 0.0-5000μm, micron accuracy

Fast measurement, 0.5s measuring interval.

Ferrous/Non ferrous thickness gauge.

Sperate thickness meter used in narrow space.

LS225+F500 Plating Thickness Gauge

Measure plating thickness below 10 μm.

Adopt digital oscillation technology.

Test fixture is optional.

Suport 1-5 points calibration.

LS225+N1500 Ultra-thin Coating thickness Tester

Test ultra-thin coating thickness below 10μm.

Eddy current measuring principle.

Test ultra-thin anodized layers on aluminum substrates.

Measuring range:0-1500μm.

LS225+N2000 Coating thickness Tester

1.Professional for measuring coating thickness with large flat area

2. Suitable for PCB board paint thickness measurement

3. Use own weight to trigger measurement, consistent pressure, stable value

4.Maximum measuring range 2000μm

Linshang coating thickness gauge measure different materials

Linshang coating thickness gauge measure different materials

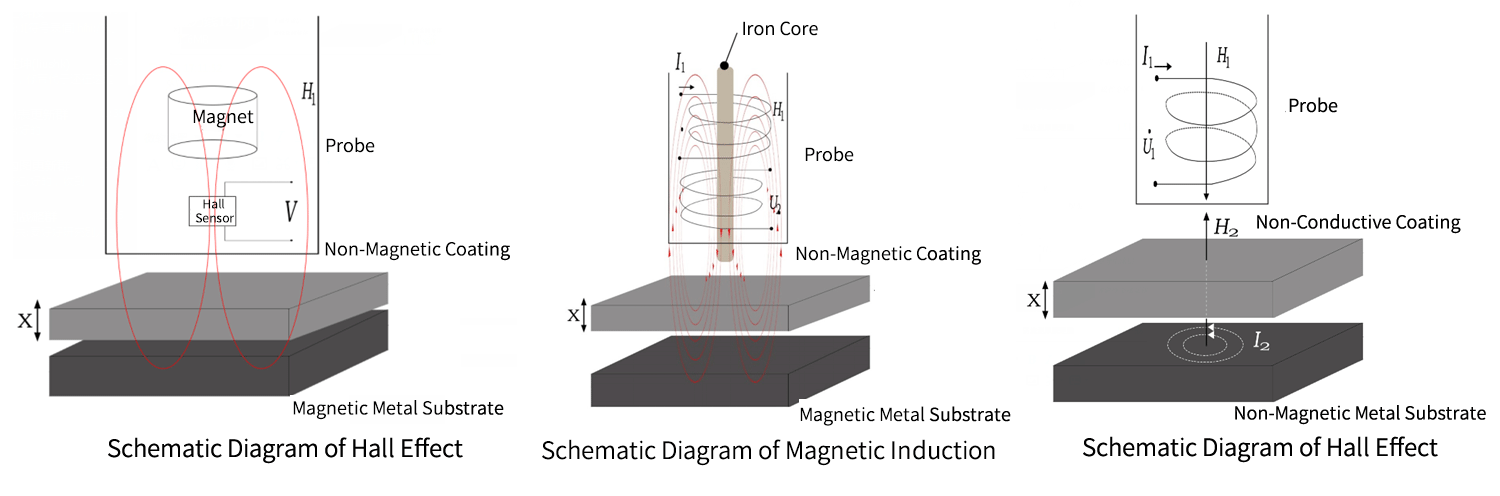

Coating thickness gauge principle

Coating thickness gauge principle