Linshang Coating Thickness Gauge Application In Different Industries

Coating thickness gauge is also called paint thickness meter. Since the coating thickness gauge on the market has been widely praised by users,it has been widely used in the thickness inspection of used car paint surface,thickness detection of steel structure anti-corrosion coating, natural gas pipeline.Anti-corrosion coating thickness detection, moisturizing cup coating thickness detection and other fields.

The Linshang coating thickness gauge combines two thickness measurement principles:magnetic thickness measurement and eddy current thickness measurement.Magnetic thickness measurement is suitable for the measurement of non-magnetic coatings on ferromagnetic metal substrates such as plastics,paints,enamels,etc.Eddy current thickness measurement is suitable for the measurement of non-conductive coatings on non-magnetic metal substrates, such as anodized films, paints, etc.The following are practical application examples of Linshang coating thickness gauges in various industries.

1.Used car paint surface thickness detection

One of the used car inspection items is the paint thickness test by the coating thickness gauge. Used car paint surface thickness inspection can avoid the second-hand car dealers receiving the accident car.Through the test of the coating thickness gauge,it can be judged whether the car paint surface has been repaired.Through the repair of the paint surface,it can be judged whether the car has accident. The case describes the whole process of testing the thickness of the Mercedes-Benz car paint with the Linshang LS220B coating thickness gauge.

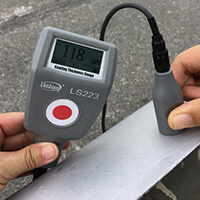

2.Corrugated guardrail anti-corrosion layer thickness detection

The cold-formed steel parts of the corrugated beam guardrail are treated with anti-corrosion treatment.The thickness of the conventional wave guardrail steel plate is about 3-4mm.The average galvanized layer thickness is greater than 84μm according to national standards.For some areas that are particularly severely corrosive or aesthetically pleasing, the steel rail members are painted after galvanizing, so that the overall coating thickness is also increased. Linshang LS223 coating thickness gauge with F3N3 probe,the range can be measured up to 3mm.It is suitable for the thickness detection of corrugated fence.

3.Thickness detection of natural gas pipeline anti-corrosion layer

The thickness of the anti-corrosion layer of the natural gas pipeline is different from that of the ground. The general anti-corrosion layer of the underground natural gas pipeline is 3mm and the anti-corrosion layer is 6mm.On the ground,3PE is generally used for anti-corrosion, a total of three layers and the coating thickness is about 3.5 mm. The Linshang LS223 coating thickness gauge with F5N3 probe, measurement range up to 5mm.It is suitable for thickness inspection of thicker coatings.

4.Thickness of the anti-corrosion layer of the communication cabinet

The material and application site of the communication cabinet are different.The thickness of the anti-corrosion coating for each communication cabinet is different according to the standard.The thickness of the anticorrosive coating is generally 0-60 μm, 61-120μm and 121-250 μm.There are many ways to detect the thickness of a coating.The most portable and fast method is to use a coating thickness gauge. The case is described in the Linshang LS223 coating thickness gauge for detecting outdoor communication cabinets.

5.Vacuum cup surface coating thickness detection

The outer surface of the stainless steel vacuum cup is plated with copper or silver, which is used to reflect heat radiation and can achieve the purpose of heat preservation.Due to the special composition of the double-layer stainless steel vacuum cup surface coating,it is necessary to set the coating thickness gauge to the iron-based measurement mode for measurement. The case describes the vacuum cup surface coating thickness measured by the Linshang LS220H coating thickness gauge, as well as the measurement principle and precautions.

6.Steel structure fire coating thickness detection

According to the standard of "steel structure fireproof coating",the quality and classification of steel structure fireproof coatings are clearly defined.The coating products can be divided into three types:thick type,thin type and ultra-thin type steel structure.For thin steel structure fireproof coatings,the Linshang LS221 coating thickness gauge can be used for testing.The thick steel structure fireproof coating can be tested with the Linshang LS223 coating thickness gauge.In the case,the specific operation method of testing the steel structure fireproof coating thickness with the LS223 coating thickness gauge is described.

7.Aluminum alloy door surface coating thickness detection

Aluminum alloy surface treatment is one of the important links in the production of aluminum alloy doors and windows.Good surface treatment has greatly improved the corrosion resistance, weather resistance and service life of doors and windows.The surface treatment of aluminum alloy mainly includes four methods: oxide film, electrophoretic painting, powder coating and fluorocarbon coating.The thickness of the aluminum alloy surface coating can be measured by the Linshang LS221 coating thickness gauge.

8.Thickness detection of fireproof coating in subway

Fire protection design and fireproof coating are generally used in subway cars to avoid fires.The "sandwich" structure is generally used in subway cars, specifically rubber floor cloth(3mm) - honeycomb board (18mm)- aluminum profile welded floor (60mm).The lower surface of the profile is coated with a layer of fire retardant coating, which includes a matching primer and fire retardant coating.The case introduces the how to measure the coating thickness at different subway positions with Linshang LS221 coating thickness gauge.